Accuracy tolerance of spherical lens

Improved TECHSPEC ® Various standard tolerances for spherical lenses. These improvements make assembly easier and can reduce complex assembly processes, such as active alignment. These improvements improve performance and make our lenses easier to integrate into OEM applications. We have improved the processes of several world-class spherical mirror manufacturing plants in Japan, Singapore and the United States, so that these precision specifications can be realized. EO can produce millions of lenses every year. Improved specifications include:

Diameter tolerance: all techspecs ® Spherical lenses, regardless of size, Manufacturer of spherical lensnow have a diameter tolerance of + 0.000 / -0.025mm. Keep the diameter tolerance at 25 μ Within m, it can be ensured that the lens can be accurately installed in the barrel assembly so that the optical axis of the lens is aligned with the mechanical axis.

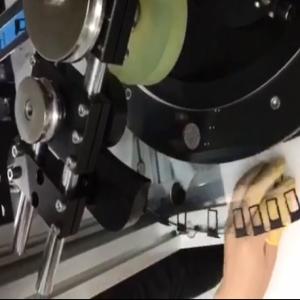

The diameter tolerance is a key mechanical tolerance that must be considered when installing optical elements. Deviation from the nominal diameter may prevent the lens from being accurately assembled in the mounting fixture, resulting in eccentricity or inclination in the optical assembly. The following figure shows a lens that is not firmly fixed in the barrel due to diameter error: